Custom CNC Machine Frames & Structures

Precision-engineered bases, beams, tables, rails, and gantries tailored to your specifications. Complete technical support and design services available.

Comprehensive CNC Machine Components

We manufacture all key structural components for CNC machines, ensuring perfect fit and performance.

Machine Bases

Heavy-duty cast or welded bases with precision leveling and vibration dampening features.

Material:Cast iron,Steel,Aluminum

Surface finish:Powder coatin, Spray painting

Size:Customized

Learn More→

Gantry with Z-axis mould

Complete bridge and gantry structures for large format CNC machines.Various styles can be customized.

Material:Cast iron,Steel,Aluminum

Surface finish:Powder coatin, Spray painting

Size:Customized

Learn More→

Parts and Assembly

Including rails, worktables, lead screws and other accessories, we can also provide customers with a one-stop service.

Material:Cast iron,Steel,Aluminum

Surface finish:Powder coatin, Spray painting

Size:Customized

Learn More→

Comprehensive Technical Support

From initial design to final production, we provide end-to-end services for your CNC machine frame project.

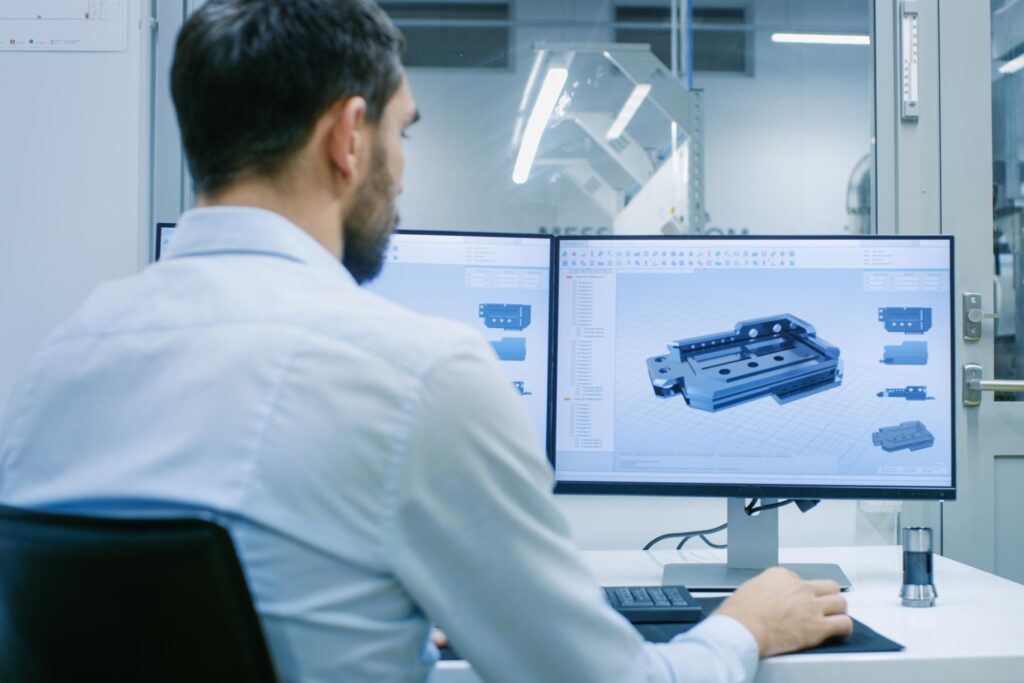

Custom Design & Engineering

Our engineering team will work with you to develop optimal frame designs based on your machine requirements, load conditions, and performance goals.

3D Modeling & Simulation

Finite element analysis to ensure structural integrity under operating conditions.

Detailed Drawings

Comprehensive manufacturing drawings with tolerances and material specifications.

Design Optimization

Weight reduction, material selection, and cost optimization while maintaining performance.

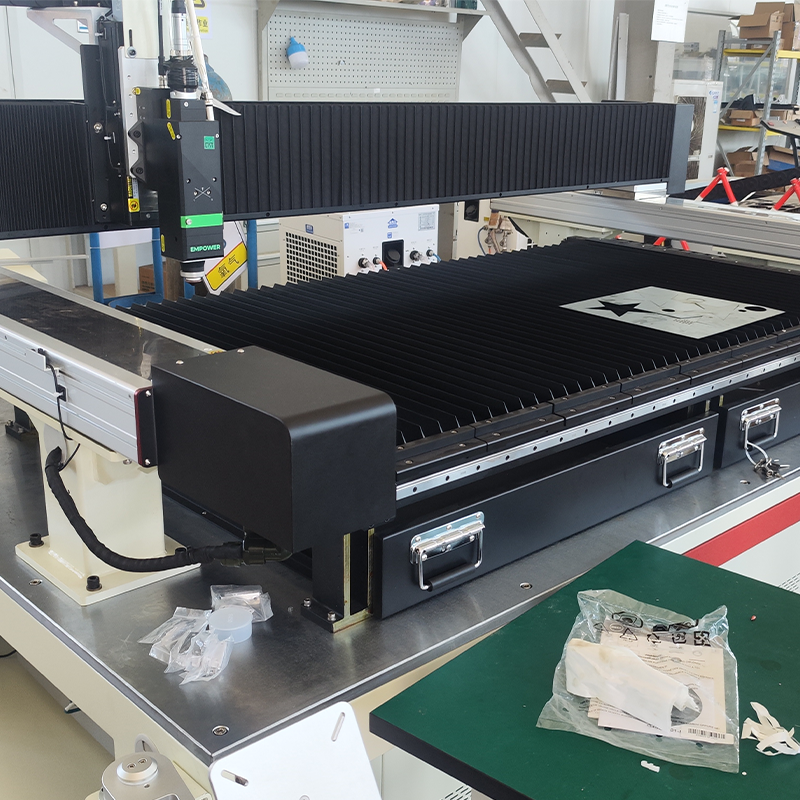

Manufacturing & Production

We utilize advanced manufacturing processes to produce high-precision machine frames that meet your exact specifications.

Precision Machining

CNC milling, turning, and grinding for tight tolerance components.

Welding & Fabrication

High-quality welding for structural components with stress relief.

Quality Inspection

Comprehensive testing and measurement to ensure compliance with specifications.

Streamlined Customization Process

We’ve developed a straightforward process to ensure your custom CNC machine frame project is completed efficiently and to your exact specifications.

Initial Consultation

We discuss your requirements, application, and specifications to understand your project needs.

Discuss machine specifications and requirements

Review application and operating conditions

Determine performance criteria and standards

Design & Engineering

Our engineers create detailed designs based on your requirements, or work from your provided drawings.

Receive and review your drawings (if available)

Create initial design concepts and proposals

Provide design recommendations and alternatives

Quotation & Approval

We provide a detailed quotation including materials, manufacturing processes, and lead times for your approval.

Detailed cost breakdown and timeline

Material specifications and options

Terms, conditions, and payment schedule

Manufacturing

We produce your custom CNC machine frame components using precision manufacturing processes.

Precision manufacturing using advanced equipment

In-process quality control and inspections

Regular progress updates and communication

Inspection & Delivery

Final inspection to ensure compliance with specifications, followed by secure packaging and delivery.

Comprehensive final inspection and testing

Certification of compliance and documentation

Secure packaging and worldwide shipping options

Advanced Manufacturing Capabilities

We invest in state-of-the-art equipment and processes to deliver the highest quality CNC machine frames.